ESEC MACHINING SOLUTIONS

The EMS (E’sec Machining Solutions) was established in the year 2022 . Our aim of establishing this machining center inside the college premises is to become the leading organization in providing CNC Machine Job Work in global level. EES has core objective of serving its customer with unmatched quality and customer delight in the field of precision machined and engineering components. The objective are met with the state of the art CNC machine shop, highly qualified and experienced technical team & dedicated skilled workers. We undertake of all types of precision components.In terms of quality and cost we would like to be the best among the leading industries. Our products will reflect our engineering excellence that combines innovation with accuracy.

Vision

Vision of Erode Sengunthar Engineering College Machining Solutions ( EMS)is to become a World Class Automation and Scientific Research Centre for the Benefit of the Society.

Mission

- Produce precision engineering components with greater accuracy at par with international standards and meet the requirement of domestic and international, employing world class facility

- Impart Value Based Technical Education to the Students from across various Socio Economic backgrounds.

Facilities @ ESEC MACHINING SOLUTIONS

Training @ ESEC Machining Solution

COURSE DETAILS:

1. CNC Turning Machine Operation & Programming

- Duration: 15 days

- Level: Beginner to Intermediate

- Prerequisites: Basic machining knowledge (manual lathe experience preferred)

- Software Used: Fanuc or G-code-based CNC simulators

- Hands-on Training: Live projects on CNC lathe machines

- Certification: CNC Turning Operator/Programmer Certificate

- Assessment: Practical machining test + written exam

Course Objectives:

- Understand CNC turning principles, components, and machine setup.

- Learn to read and interpret engineering drawings for turning operations.

- Master G-code and M-code programming for CNC lathes.

- Operate CNC turning machines safely, including tool and workpiece setup.

- Perform facing, turning, grooving, threading, and taper turning operations.

- Optimize cutting parameters (speed, feed, depth of cut) for efficiency.

- Troubleshoot common CNC turning errors and tool wear issues.

- Apply quality control techniques using precision measuring instruments.

Course Outcomes:

- Explain CNC Turning Fundamentals.

- Interpret Engineering Drawings.

- Write CNC Turning Programs.

- Safely Operate CNC Lathes.

- Perform Machining Operations.

- Optimize Machining Parameters.

- Diagnose & Resolve Issues.

- Ensure Quality Standards.

2. CNC Milling Machine Operation & Programming

- Duration: 15 days

- Level: Beginner to Intermediate

- Prerequisites: Basic machining knowledge (manual milling preferred).

- Software Used: Fanuc, or CAM software.

- Hands-on Training: Practical sessions on 3-axis CNC milling machines

- Certification: CNC Milling Operator/Programmer Certificate

- Assessment: Practical machining test + written exam

Course Objectives:

- Understand CNC milling machine components, axes, and operations.

- Read and interpret part blueprints for milling applications.

- Write and edit G-code programs for 2D and 3D milling operations.

- Set up tools, workholding devices, and workpiece zero positions.

- Perform face milling, pocketing, drilling, contouring, tapping and slotting.

- Optimize machining parameters for surface finish and tool life.

- Operate CNC milling machines with safety protocols.

- Inspect finished parts using micrometers and calipers.

Course Outcomes:

- Explain CNC Milling Fundamentals.

- Interpret Part.

- Program CNC Milling Machines.

- Set Up Machines & Workpieces.

- Perform Machining Operations.

- Optimize Machining Parameters.

- Apply Safety Best Practices.

- Inspect Finished Parts.

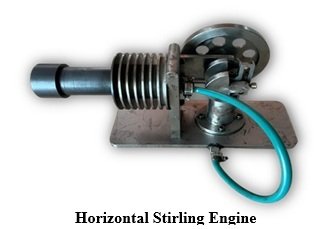

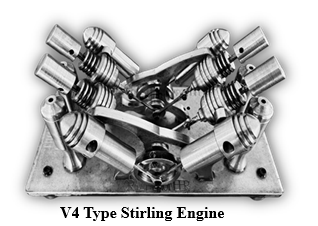

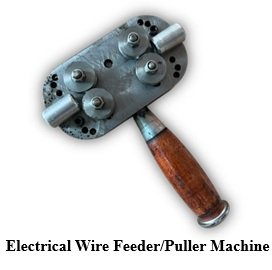

Products Developed at ESEC Machining Center

INDUSTRIAL DEVELOPMENT JOBS

PRODUCTION JOB ORDERS CARRIED OUT AT ESEC-CNC MACHINING CENTRE

DESIGNER PRODUCTS DEVELOPED AT ESEC-CNC MACHINING CENTRE