Chemical Engineering

Lab facilities

- Chemical Reaction Engineering Lab

- Heat Transfer Lab

- Mass Transfer Lab

- Organic Chemistry Lab

- Mechanical Operation Lab

- Technical Analysis Lab

- Physical Chemistry Lab

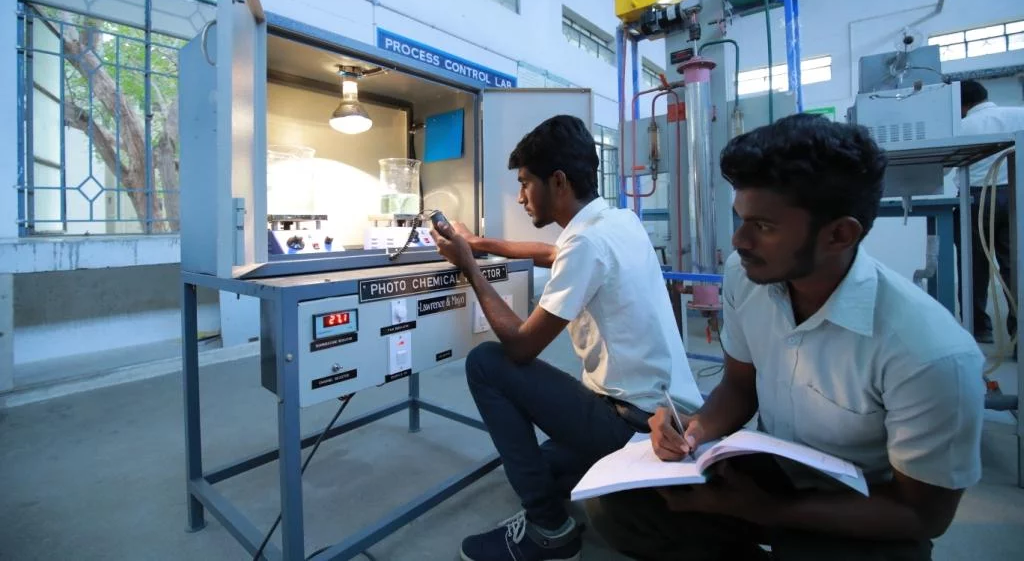

- Process Control Lab

Chemical Reaction Engineering Laboratory

| Sl. No. | Name of the major Equipment | Quantity |

|---|---|---|

| 1 | Batch reactor | 3 |

| 2 | Plug flow reactor | 1 |

| 3 | CSTR | 2 |

| 4 | Sono Chemical Reactor | 1 |

| 5 | Photochemical reactor | 1 |

| 6 | Packed bed reactor | 1 |

FLUID SOLID CATALYTIC REACTOR

SONOCHEMICAL REACTOR

SONOCHEMICAL REACTOR

PLUG FLOW REACTOR

PLUG FLOW REACTOR

Heat Transfer Laboratory

| Sl. No. | Name of the major Equipment | Quantity |

|---|---|---|

| 1 | Cooling Tower | 1 |

| 2 | Tray Dryer | 1 |

| 3 | Open Pan Evaporator | 1 |

| 4 | Boiler | 1 |

| 5 | Packed Bed | 1 |

| 6 | Double Pipe Heat Exchanger | 1 |

| 7 | Bare and Finned Tube Heat Exchanger | 1 |

| 8 | Condenser | 1 |

| 9 | Helical Coil | 1 |

| 10 | Agitated Vessel | 1 |

ROTATING DISC CONTACTOR

ROTATING DISC CONTACTOR

Mass Transfer Laboratory

| Sl. No. | Name of the major Equipment | Quantity |

|---|---|---|

| 1 | Simple Distillation setup | 2 |

| 2 | Steam distillation setup | 1 |

| 3 | Packed column | 1 |

| 4 | Liquid-liquid extractor | 1 |

| 5 | Vacuum Dryer | 1 |

| 6 | Tray dryer | 1 |

| 7 | Rotary dryer | 1 |

| 8 | Ion exchange column | 1 |

| 9 | Rotating disc contactor | 1 |

| 10 | Cooling tower | 1 |

| 11 | Absorption column | 1 |

PACKED BED REACTOR

PACKED BED REACTOR

VACCUM DRYER

VACCUM DRYER

Organic Chemistry Laboratory

| Sl. No. | Name of the major Equipment | Quantity |

|---|---|---|

| 1 | Silica Crucible | 10 |

| 2 | Heating Mantle | 2 |

| 3 | Muffle Furnace | 1 |

| 4 | Hot air oven | 1 |

| 5 | Desiccator | 5 |

| 6 | Vacuum pump | 1 |

| 7 | Condenser | 10 |

| 8 | Reflux Condenser | 2 |

Mechanical Operation Laboratory

| Sl. No. | Name of the major Equipment | Quantity |

|---|---|---|

| 1 | Sieve shaker | 2 |

| 2 | Leaf filter | 2 |

| 3 | Plate and Frame Filter Press | 2 |

| 4 | Sedimentation Jar | 2 |

| 5 | Jaw Crusher | 1 |

| 6 | Ball Mill | 2 |

| 7 | Cyclone Separator | 1 |

| 8 | Roll Crusher | 1 |

| 9 | Elutriator | 2 |

| 10 | Drop Weight Crusher | 1 |

| 11 | Sieves | 3 |

Technical Analysis Laboratory

| Sl. No. | Name of the major Equipment | Quantity |

|---|---|---|

| 1 | Silica Crucible | 20 |

| 2 | Heating Mantle | 3 |

| 3 | Muffle Furnace | 1 |

| 4 | Hot air oven | 1 |

| 5 | Desiccator | 5 |

| 6 | Vacuum pump | 1 |

| 7 | Condenser | 10 |

| 8 | Reflux Condenser | 2 |

| 9 | Pensky martens closed cup apparatus | 1 |

| 10 | Cleveland open cup apparatus | 1 |

| 11 | Cloud point apparatus | 1 |

| 12 | Aniline point apparatus | 1 |

| 13 | Saybolt Viscometer | 1 |

| 14 | Redwood viscometer | 1 |

| 15 | Bomb Calorimeter | 1 |

| 16 | Junkers gas Calorimeter | 1 |

| 17 | Conductivity meter | 5 |

| 18 | pH meter | 5 |

Physical Chemistry Laboratory

| Sl. No. | Name of the major Equipment | Quantity |

|---|---|---|

| 1 | Silica Crucible | 20 |

| 2 | Heating Mantle | 3 |

| 3 | Muffle Furnace | 1 |

| 4 | Hot air oven | 1 |

| 5 | Desiccator | 5 |

| 6 | Vacuum pump | 1 |

| 7 | Condenser | 10 |

| 8 | Reflux Condenser | 2 |

| 9 | Pensky martens closed cup apparatus | 1 |

| 10 | Cleveland open cup apparatus | 1 |

| 11 | Cloud point apparatus | 1 |

| 12 | Aniline point apparatus | 1 |

| 13 | Saybolt Viscometer | 1 |

| 14 | Redwood viscometer | 1 |

| 15 | Bomb Calorimeter | 1 |

| 16 | Junkers gas Calorimeter | 1 |

| 17 | Conductivity meter | 5 |

| 18 | pH meter | 5 |

| Sl. No. | Name of the major Equipment | Quantity |

| 1 | Micro Calorimeter | 1 |

| 2 | Beckman Thermometers Glasswares | 3 |

| 3 | Thermometers 0 to 110 0° | 10 |

| 4 | Bottle Shakers | 1 |

| 5 | pH meters | 3 |

| 6 | Pressure Glass bottles | 2 |

| 7 | Standard Cells | 2 |

| 8 | Multimeters | 2 |

| 9 | Viscometers | 5 |

| 10 | Ostwald | 5 |

| 11 | Cannan Ubbelholde | 0 |

| 12 | Voltage Stabilizer | 2 |

| 13 | Stalalgmometer | 1 |

| 14 | Surface Tension Meter. Tape Heaters | 0 |

| 15 | Mantle Heaters | 5 |

| 16 | DC Power Supply | 2 |

| 17 | Thermostat | 1 |

| 18 | Cryostats | 1 |

| 19 | Conductometer | 5 |

| 20 | Potentiometer | 5 |

| 21 | Polarimeter | 1 |

| 22 | Refractometer | 1 |

Process Control Laboratory

| Name of the major Equipment | Quantity | |

|---|---|---|

| Sl. No. | ||

| 1 | U tube manometer with controller | 1 |

| 2 | Interacting Tank | 1 |

| 3 | Non Interacting Tank | 1 |

| 4 | Open loop control system | 1 |

| 5 | Closed loop control system | 1 |

| 6 | ON/OFF controller | 1 |

| 7 | Control valve characteristics | 1 |

| 8 | Pressure Tuner | 1 |

| 9 | Temperature Tuner | 1 |

| 10 | Proportional Controller | 1 |

| 11 | Flow Transmitter | 1 |

| 12 | Level Transmitter | 1 |

| 13 | Cascade control system | 1 |